Description

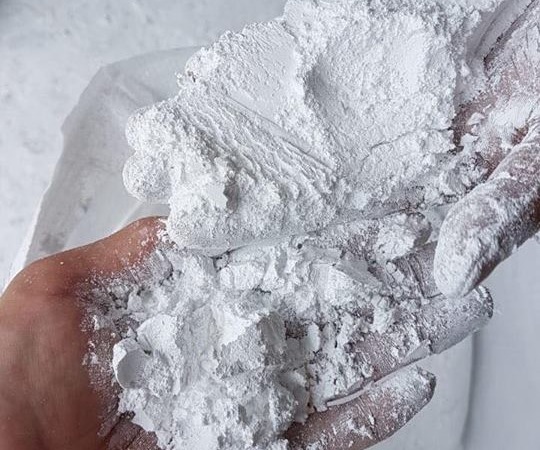

Coated Calcium Carbonate Powder is a form of limestone powder that has been surface-treated, usually with stearic acid or other fatty acids. This coating improves dispersion, water resistance, and compatibility in polymer applications.

Raw material is exploited from MONG SON mountain Pit with highest purity limestone that is one of top 5 sources in the world comparing with Brazil, Malaysia, Egypt.

Surfacetreated with stearic acid (1% coating)

Hydrophobic properties

Enhances smoothness and dispersion

Prevents agglomeration and improves mixing efficiency

Calcium Carbonate - CaCO₃

Iron Oxide - Fe₂O₃

Aluminum Oxide - Al₂O₃

Magnesium Oxide - MgO

Silicon Oxide - SiO₂

Titanium Dioxide - TiO₂

Sodium Oxide - Na₂O

Potassium Oxide - K₂O

Copper Oxide - CuO

Lead Oxide - PbO

> 98.5%

< 0.02%

< 0.03%

< 0.08%

< 0.03%

0.00%

0.00%

0.00%

0.00%

0.00%

Whiteness

Brightness

Hardness

Moisture Content

DOP Absorption

Density

PH

Specific Surface Area

98% Min

95% Min

2.5 Moh

0.2% Max

0.2% Max

2.7g/cm³

8-9

5.40m²/g

ATC8 (1820 Mesh)

ATC10 (1500 Mesh)

ATC12 (1200 Mesh)

ATC15 (1000 Mesh)

ATC17 (800 Mesh)

ATC20 (730 Mesh)

ATC25 (600 Mesh

ATC27 (500 Mesh

D50 = 1.5 ± 0.2 µm

D50 = 2.0 ± 0.2 µm

D50 = 2.3± 0.3 μm

D50 = 2.5 ± 0.3 μm

D50 = 2.7 ± 0.3 μm

D50 = 3.0 ± 0.3 μm

D50 = 3.5 ± 0.3 μm

D50 = 3.7 ± 0.3 μm

D97 = 8.0 ± 1.0 µm

D97 = 10 ± 1.0 µm

D97 = 12 ± 2.0 μm

D97 = 15 ± 2.0 μm

D97 = 17± 2.0 μm

D97 = 20 ± 2.0 μm

D97 = 25 ± 3.0 μm

D97 = 27 ± 3.0 μm

Coated Calcium Carbonate Powder is treated with a fatty acid surface coating, typically stearic acid, to improve dispersion, water resistance, and compatibility in polymer applications. It is widely used in plastic manufacturing, masterbatches, and high performance composite materials. This surface treated product enhances the bonding strength with polymers, ensuring better mechanical properties and processing efficiency.

PAINTS AND COATINGS

Used as a pigment extender and to improve opacity and brightness.

PAPER INDUSTRY

Helps in paper whitening and improving printability.

PLASTICS AND RUBBER INDUSTRY

Acts as a filler to enhance the elasticity, strength and reduce production costs in plastics & rubber products

CONSTRUCTION MATERIALS

Used in cement, concrete, and as a filler in adhesives and sealants.

MASTERBATCH AND COMPOUNDING

Used in plastic compounding to ensure even distribution of fillers.

Reviews

There are no reviews yet.